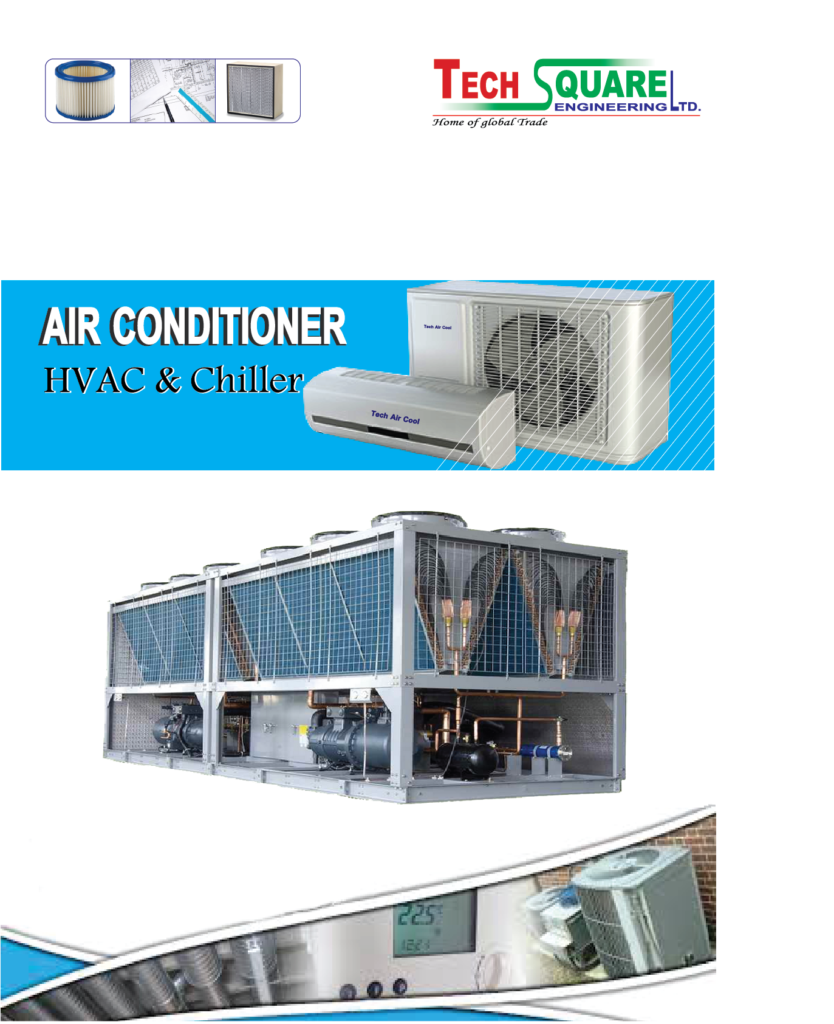

22 Years Of Experience In Water Chiller Manufacturing, find the right cooling equipment. Industrial Chiller supply, Stable and efficient, with strong refrigeration capacity. Water Cooled Chiller. Industrial Chiller. Factory direct sales. Air Cooled Scroll Chiller.

Which industrial applications need water chiller?

Industrial water chillers of Xiecheng are widely used in many industries like plastic and rubber manufacturing, electronic productions, electroplating, medical chemistry, ultrasonic cooling and printing business, etc. It can accurately controls the cooling temperature of modern facilities.

What is water chiller?

Chiller is a equipment for cooling water and providing stable temperature, flow and pressure. The working principle of a water chiller is to first input certain water into its internal tank, through the chiller cooling system the water would be cooled down, then the internal pump would pump out this cooled water into subject device(s) and take out the heat of the device(s); and the warm or hot water occurred would go back into the chiller tank for a new cooling cycle heat exchange, hence to realize the cooling of a device.

Why do I need water chiller?

Industrial water chiller could accurately provide needed temperature for modern industrial manufacturing and largely improve efficiency and product quality. Like the water chiller is to provide a cooling process in plastic molding, to improve quality of molded products and shorten period of injection molding cycles. Hence maximizes productivity of plastic molding manufacturing.

How do I choose water chiller?

Chiller are divided with air cooled type and water cooled type while water cooled type could be further divided into box type and screw type.

● Air cooled Chiller: If the workshop condition is dry and with no case of powder, under good ventilation, it’s optional for air-cooled chiller due to its convenience on installation and moving with the help of air type condenser and fan which does not require additional cooling tower for radiation.

● Water cooled box type chiller: If there’s already cooling tower in the facility, it’s optional for water-cooled type chiller for it’s required to work with cooling tower and pump to process hot water to reach better radiation.● Screw type chiller: For better cooling result and longer life time using, screw type chiller or chiller unit is required.

Which industrial applications need water chiller?

What is water chiller?

Chiller is a equipment for cooling water and providing stable temperature, flow and pressure. The working principle of a water chiller is to first input certain water into its internal tank, through the chiller cooling system the water would be cooled down, then the internal pump would pump out this cooled water into subject device(s) and take out the heat of the device(s); and the warm or hot water occurred would go back into the chiller tank for a new cooling cycle heat exchange, hence to realize the cooling of a device.

Why do I need water chiller?

Industrial water chiller could accurately provide needed temperature for modern industrial manufacturing and largely improve efficiency and product quality. Like the water chiller is to provide a cooling process in plastic molding, to improve quality of molded products and shorten period of injection molding cycles. Hence maximizes productivity of plastic molding manufacturing.

How do I choose water chiller?

Chiller are divided with air cooled type and water cooled type while water cooled type could be further divided into box type and screw type.

● Air cooled Chiller: If the workshop condition is dry and with no case of powder, under good ventilation, it’s optional for air-cooled chiller due to its convenience on installation and moving with the help of air type condenser and fan which does not require additional cooling tower for radiation.